UN Series

Universal injection molding machine(110T-2100T)

The most cost-effective perfect combination of leading technology and optimal price

Manual download

- introduction

- Machine

- System

- other

INTRODUCTION

UN Series

DRIVE TECHNOLOGY

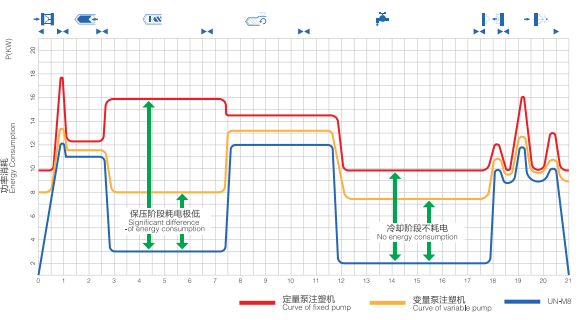

equipped with high performance servo system. The output power of the servo motor changes with load, without loss of excess energy.

During pressure holding, the motor reduces the speed and theenergy consumption is extremely low. The motor does not workduring cooling and the energy consumption is zero. Improves injection accuracy while saving power, water and reducing noise. A real new revolution in hydraulic injection molding machines.

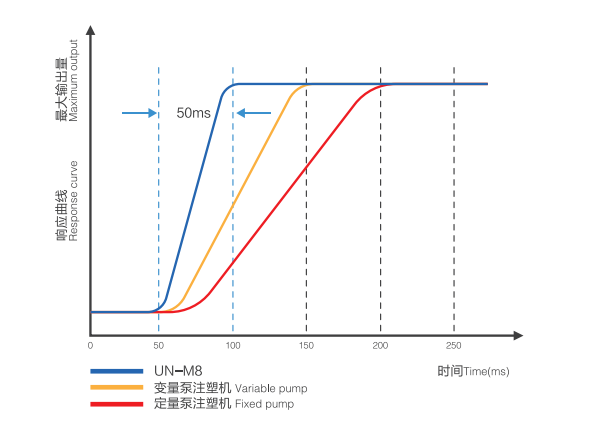

High response

Equipped with a high response servo motor and internal gear pump system,UN-M8 reaches maximum output at only 0.05s, significantly faster compared to traditional hydraulic injection molding machines, effectively shortening the cycle and improving production efficiency.

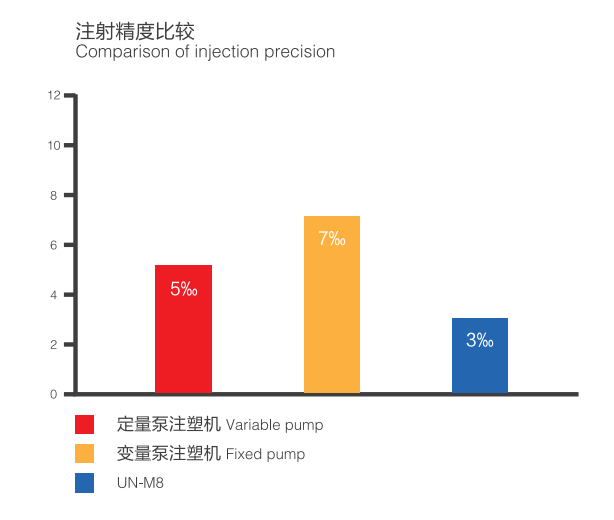

High reproducibility

The precision of UN-M8 is superimposed on the precision of the internal gear pump, and form a closed loop through high sensitive pressure feedback device.The injection repeatability able to reach 3‰,which shows better injection stability than traditional hydraulic machine and the rate of qualified molding parts is increased signiticantly.

FEATUREES

UN Series FEATUREES

-

01

High precision linear guide injection structure

The injection and plasticizing system adopts linear guide with high precision, high rigidity and low friction, provides lowresistance and stable movement during injection and plasticizing. Adjustable and sensitive, better for materials in low viscosity and requires high temperature.

-

02

Adjustabie wear-resistant sliding foot of moving platen

Siding foot adopts special wear-resistant matorial, able to adjust the heigh and balance the weight,durable and clean.

-

03

Professional plasticizing and injection solutions

Professional screw and barrel for different kinds of rawmaterials and processes, to improve quality of themolding parts.

-

04

Modular enetpy-saving and high-response oil circuit design

Increases speed by more than 25%.

-

05

Built-in high efficiency oil cooler

Small volume, high cooling efficiency, simple oil circuit, toguarantee stable oil temperature.

-

06

Intelligent lubrication distribution system

Evon oil distribution,high lubrication efficiency and extends toggle life

-

07

Oplimized design of high rigidity and precision clamping system

Opumized platen design, ons-pliece catting of toggle seat and movingplaten; one ploce casting of crosshead guide suppont, toggle toat and rearploten lt not oniy improves the rigidity but also the accuracy of mold opening.

CONTROL SYSTEM

UN Series CONTROL SYSTEM

ELECTRONIC CONTROL SYSTEM

Equipped with special controller for injection molding machine, adopts full digital control and multiple CPU division processing to improve the control system execution speed and machine working accuracy. And monitor the production process in real time, showing various fault diagnosis. Able to eqiup with MES system to realize network management of production workshop.

OTHERS

UN Series OTHERS

-

Product case

Injection molding plastic products need injection molding machine to injection molding. The plastic parts of automobile interior, such as leaf board, toy shell, clothing accessories, charging head and electronic connector, are all finished by injection molding machine. Its industries can cover: baby toys, computers, toothbrush handles, accessories, golf balls, broochs, antennas, badges, buttons, chargers, electrical appliances, stationery, lampshade, instrument case cover, case, furniture, sporting goods, gears, tableware, surfaces, decorations, glue flowers, small building materials, automobiles, instruments, electronic parts, connectors, telecommunications, Keychains, toys, plugs, etc Socket, connector, switch, backpack buckle, plastic bottle connector, pen making, cosmetic bottle connector, sole, color board, etc